Inventory of Innovative Indoor Smoke

Alleviating Technologies in Nepal

11

ash is spread on the brick shaped wooden mould which

is soaked in water for 30 minutes before casting bricks.

The prepared paste is then put in the mould and pressed

and levelled. After levelling the paste, the mould with

paste is overturned and the mould is removed slowly.

The prepared block is sun dried for 3 to 4 days.

The construction of the stove starts with preparation of

bricks and soil paste. Soil paste is used to join the bricks

and to fill up the small opening to make it air tight. A

layer of stones is fixed on the floor and a gap of two

inch is maintained between the kitchen wall and stove

wall. The gap is filled either with husk or ash for

insulation. Metal plate or metal rods/rings is placed

around the pothole for additional strength to prevent

the stove from cracking while cooking.

The outlet of the chimney, which is usually made of

metal (varying in shapes and sizes) is extended outside

through the hole of the kitchen wall. The chimney height

is maintained at 5 feet because longer chimney sucks

the flame and hot air thereby reducing the eifficiency

of the stove and the shorter chimney cannot create

sufficient draft. During construction, a small hole is made

on the stove at chimney side to remove soots deposited

in the chimney. Chimney should be bend free to prevent

pressure loss and ensure proper draft.

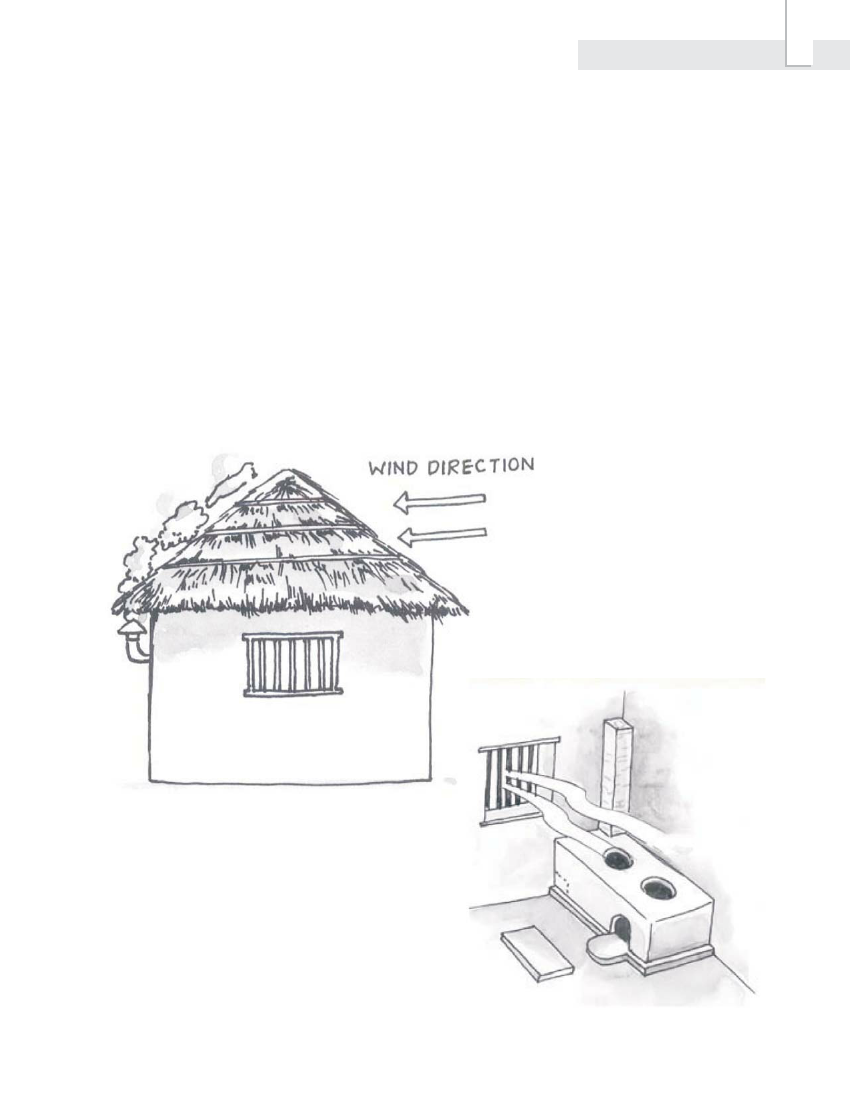

Chimney should be cleaned off from soots at least once

in 15 to 25 days. As these stoves are not portable,

wind direction should be considered before designing

the kitchen and especially the location of stove.

Ambient air, which contains oxygen for proper

combustion is denser than the smoke. So the kitchen

window should face the wind direction for proper

combustion as well as removal of smoke from the

kitchen as shown in Figure 3.2. Various types of mud-

brick ICS are described below.

Figure 3.2: Kitchen design consideration